How to use container desiccant correctly?

Using container desiccants correctly is crucial for effectively controlling moisture inside shipping containers and preventing damage to goods during transit. Here are some steps to use container desiccants properly:

Choose the Right Desiccant: Select a desiccant product that is[- suitable for the specific conditions of your cargo and the length of the journey. Different desiccants have different absorption capacities and are designed for varying levels of humidity.

Calculate Required Amount: Determine the amount of desiccant needed based on the volume of the container and the moisture sensitivity of the cargo. Many desiccant manufacturers provide guidelines or calculators to help with this.

Placement: Place the desiccant packets evenly throughout the container, considering the airflow patterns. It’s essential to distribute them strategically to ensure maximum coverage and effectiveness.

Secure Placement: Ensure that the desiccant packets are securely placed to prevent them from shifting during transport, which could potentially reduce their effectiveness. You can use adhesive strips or brackets to keep them in place.

Monitor Humidity Levels: Use humidity indicators or moisture meters to monitor the humidity levels inside the container during transit. This helps you assess the performance of the desiccants and take any necessary actions if moisture levels exceed the desired range.

Replace as Needed: Depending on the duration of the shipment and the absorption capacity of the desiccants used, you may need to replace them periodically. Regularly check the condition of the desiccant packets and replace them if they become saturated.

Follow Manufacturer Guidelines: Always follow the manufacturer’s instructions for the specific desiccant product you are using. They may provide additional recommendations or precautions to ensure optimal performance.

Seal Container Properly: Ensure that the container is properly sealed to prevent moisture ingress from external sources, such as rain or seawater. Inspect the container for any leaks or damage that could compromise its integrity.

By following these steps, you can effectively use container desiccants to control moisture levels and protect your cargo during shipping.

How much container desiccant use in my container?

The quantity of container desiccant required depends on container size, cargo type, transit duration, and humidity levels. However, consult your desiccant supplier or logistics expert for tailored advice to safeguard your goods effectively during shipment. Below is a chart provided, which will give you an idea of how much desiccant your container will need.

Suggested dosage of Best Dry 1000g

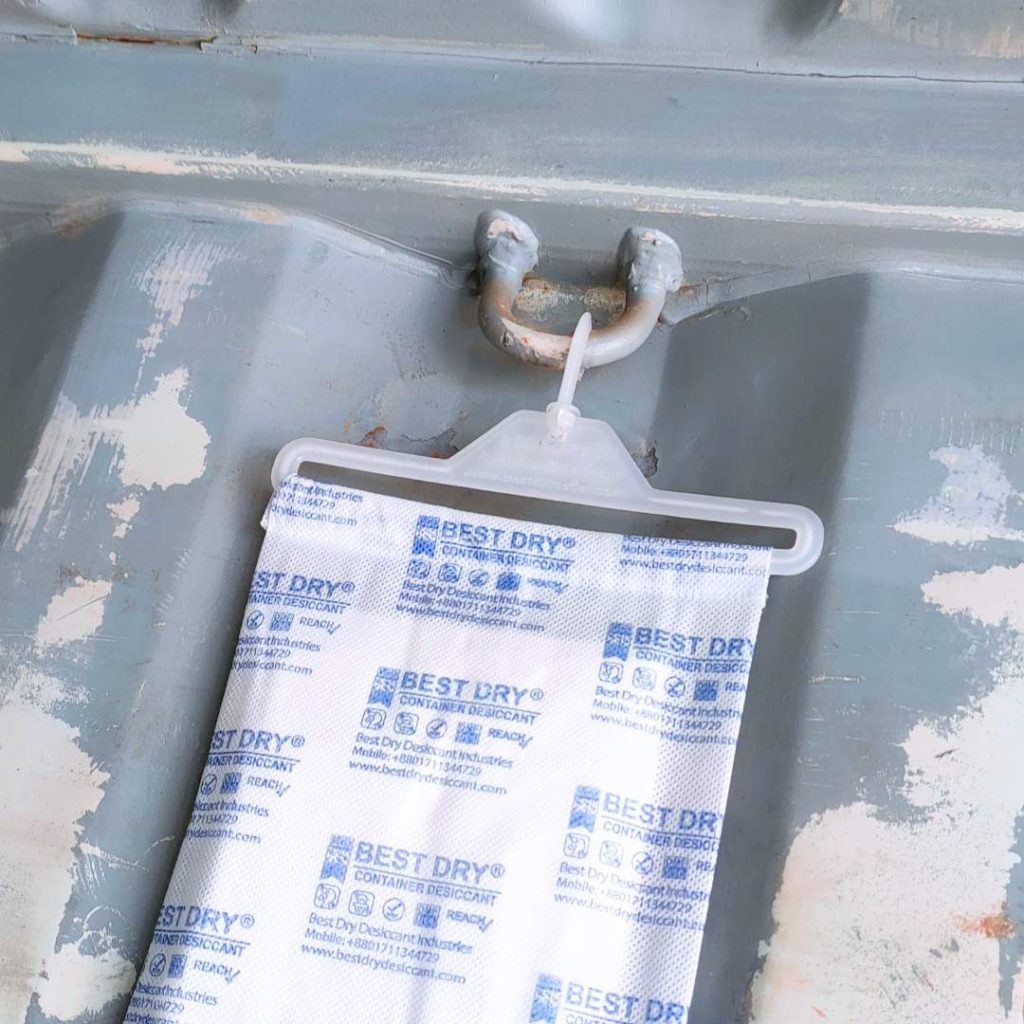

How to hanging Container Desiccant in the container?

To hang container desiccant efficiently, start by evenly dispersing it throughout the container. Hang the Container Desiccant with the hooks that are inside the container. Utilize hooks or hang it from the ceiling using ropes or cords, ensuring it doesn’t obstruct airflow. Alternatively, position it on pallets or shelves, keeping it away from direct contact with goods. Avoid covering ventilation ducts or stacking items on top of the desiccant, as this may hinder its effectiveness. This method promotes optimal moisture absorption, safeguarding your cargo from potential damage during transportation.