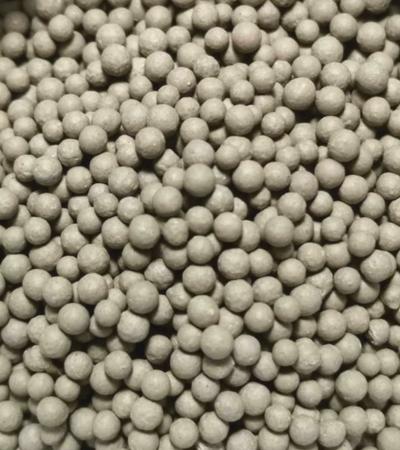

Natural Clay Desiccant

Natural Clay is actually one kind of desiccant that originated from completely natural clay. It’s produced with processed real mud in a way of the natural procedure. That’s why it is totally harm-free and environmentally safe due to not using harsh chemicals and non-toxic materials. Besides, Natural Clay Desiccant is eco-friendly and DMF-free as well.

Speciality

The natural clay desiccant actually works through the process of adsorption, where the clay attracts and holds water molecules on its surface. Moreover, it is effective in maintaining the dryness of the surrounding environment, making it useful in packaging, storage, and transportation of goods where moisture control is crucial.

Materials

Natural clay desiccants are typically made from bentonite clay, a naturally occurring absorbent material. The unique properties of bentonite clay make it well-suited for use as a desiccant.

Why is natural clay desiccant named natural?

Natural clay desiccants are considered eco-friendly for many reasons:

1. Renewable and abundant resource: Clay is a naturally occurring material found in abundance in many parts of the world. It is sourced from the earth and does not require extensive energy or resource-intensive processes to produce.

2. Biodegradable: Clay is a natural substance that is biodegradable, meaning it can break down and return to the environment without leaving behind harmful residues. When disposed of, clay desiccants will not contribute to long-term pollution or environmental harm.

3. Non-toxic: Clay desiccants are typically made from natural clays without the addition of harmful chemicals or synthetic materials. They are non-toxic and safe to handle, making them suitable for various applications, including food and pharmaceutical packaging.

4. Reusable and recyclable: Clay desiccants can often be reused multiple times, which reduces waste and promotes sustainability. After use, they can be regenerated by removing the absorbed moisture, making them ready for reuse. Additionally, some manufacturers offer recycling programs where used clay desiccants can be returned and processed for reuse.

5. Energy-efficient production: The manufacturing process for clay desiccants is relatively energy-efficient compared to alternatives such as synthetic desiccants. Clay is typically mined, processed, and shaped into desiccant packets or bags without requiring extensive energy-intensive processes.

6. Low carbon footprint: As a naturally occurring material, clay desiccants have a relatively low carbon footprint compared to synthetic alternatives. The extraction and processing of clay typically involve fewer energy-intensive steps, resulting in lower greenhouse gas emissions during production.

However, it’s important to note that the overall eco-friendliness of clay desiccants can vary depending on factors such as transportation distance, packaging materials, and disposal methods. To ensure maximum sustainability, it’s essential to consider the entire life cycle of the product, including its production, use, and end-of-life management.

Packing Paper

We use eco-friendly air filter paper for packaging natural clay desiccant. But we have more paper items:

✔️ High Quality Filter Paper

✔️ Non-woven Fabric

✔️ Composite Paper

✔️ And as per buyer requirement

Packet Size

We use high-quality ink to print the paper which is fully washable. No other way to be discolored the packet we provide. And besides, we manufacture various sizes of packets, such as, 1gm, 2gm, 3gm, 5gm, 20gm, 50gm and as per buyer requirement.

Why I need to use silica gel?

The pros & cons of using natural clay desiccant