How to Use Container Desiccants Correctly?

Shipping products overseas involves risks, especially moisture damage. Container desiccants, such as our high-quality container desiccants at Best Silica Gel Packaging, are essential to prevent moisture-related issues during transit. However, the effectiveness of desiccants depends significantly on their correct usage. Follow this comprehensive guide to ensure optimal results.

Step 1

Determine the Correct Amount of Desiccants

Before shipping, calculate the required amount of container desiccants based on the following factors:

Container Size (20ft, 40ft, 40ft High Cube)

Transit Time

Product Type (garments, electronics, furniture, pharmaceuticals, etc.)

Expected humidity and temperature variations during transit

Tip:

Typically, a 20ft container requires around 4-6 kg of container desiccants, whereas a 40ft container may need 8-12 kg. Adjust accordingly based on your shipment specifics.

Step 2

Inspect the Container

Thoroughly inspect the container for any damage or leaks before loading:

Ensure container walls, floors, and doors are dry and clean.

Verify container seals and doors close tightly without gaps or visible holes.

Repair or replace any defective containers before loading goods.

Step 3

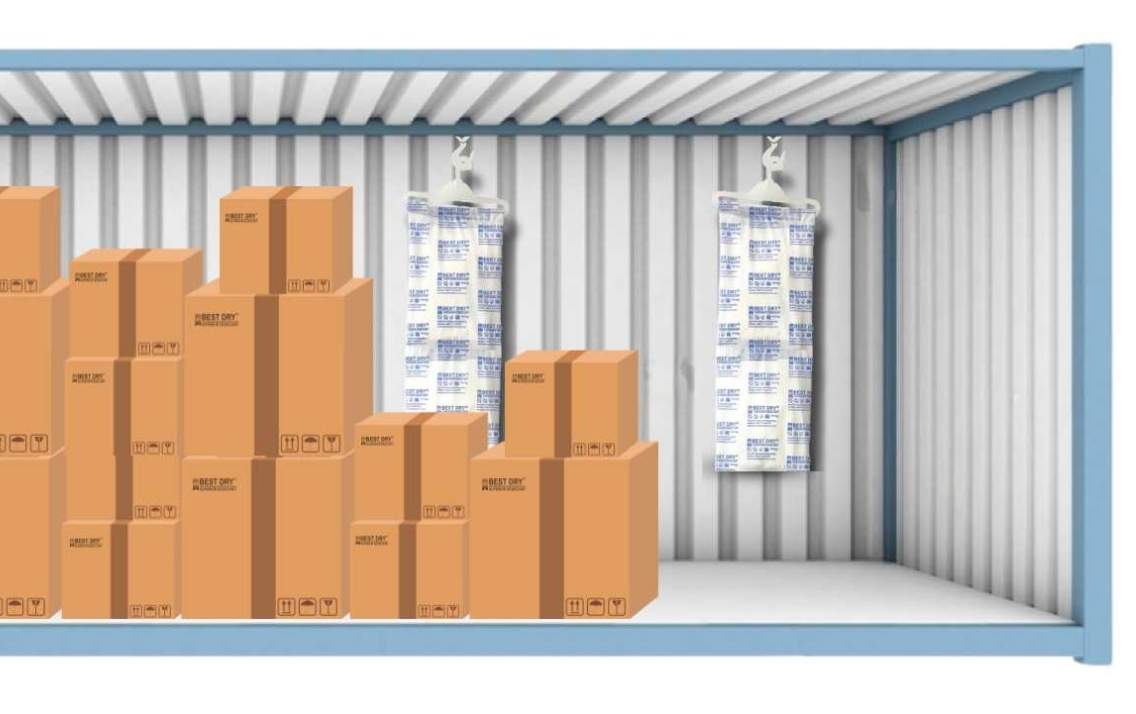

Strategic Placement of Desiccants

Correct placement maximizes desiccant performance:

Hang container desiccant bags evenly along container walls or ceiling hooks.

Avoid placing desiccants directly on the cargo, as this may limit airflow and effectiveness.

Ensure desiccants are accessible to moisture-laden air and not blocked by packaging.

Ideal Placement Locations:

Container corners

Container walls or ceiling

Near doors (highest moisture infiltration area)

Step 4

Properly Load Your Goods

Effective loading complements desiccant use:

Maintain proper ventilation and spacing between goods to enhance airflow.

Use wooden pallets or spacers beneath cargo to prevent direct floor contact.

Avoid overpacking, as it obstructs airflow and reduces moisture absorption capability.

Step 5

Seal the Container Correctly

After loading goods and placing desiccants, ensure a tight container seal:

Double-check container doors and rubber seals before departure.

Immediately close and seal doors after desiccant installation to prevent humidity intrusion.

Apply security seals to prevent unauthorized access and air exchange during transit.

Step 6

Monitor Conditions if Possible

If your shipping provider allows, monitor conditions within the container periodically:

Some shipments may permit the installation of humidity indicators or sensors to verify moisture levels.

Digital humidity and temperature data loggers can provide accurate information during and after transit.

Common Mistakes to Avoid When Using Container Desiccants

Avoid these frequent mistakes to maintain optimal effectiveness:

Underestimating quantity: Too few desiccants result in insufficient moisture control.

Incorrect placement: Direct placement on cargo or improper spacing significantly reduces effectiveness.

Improper container sealing: Any gaps or leaks drastically diminish desiccant effectiveness by continuous moisture ingress.

Ignoring container condition: Damaged or damp containers compromise desiccant efficiency.

Why Choose Best Dry Container Desiccants?

At Best Silica Gel Packaging, we provide industry-leading container desiccants tailored for international shipments. Our desiccants are:

Highly absorbent, effectively reducing humidity inside containers.

Manufactured to global standards (ISO-certified and DMF-free).

Environmentally friendly and safe for all types of goods, including food, pharmaceuticals, electronics, and garments.

Available in convenient sizes and easy-to-install packaging.

Get Expert Assistance

Still unsure about your specific requirements? Contact our expert team at Best Silica Gel Packaging for guidance in calculating the exact quantity and best usage practices for your container desiccants.